Building a Circular Future:

EPR’s Role in Precious Metal Recovery

Every outdated gadget holds more value than we imagine. Beneath the layers of plastic and glass in discarded electronics are trace amounts of precious metals. These finite resources often end up in landfills rather than being recovered and reused. As India faces a growing e-waste challenge, Extended Producer Responsibility (EPR) is emerging as a powerful sustainability solution that can help recover value and reduce environmental damage.

In this blog, we explore how EPR is driving a shift toward sustainable resource recovery and how Re Sustainability Reldan is leading this transformation.

What is EPR and Why It Matters?

Extended Producer Responsibility is a policy mechanism that holds manufacturers responsible for the post-consumer stage of their products. Under India’s e-waste management rules, producers are required to collect and recycle a specified percentage of the waste generated from their electronic products.

EPR is more than a regulatory requirement. It is a catalyst for sustainability. It promotes eco-friendly product design, supports the development of formal recycling infrastructure, and enables recovery of valuable materials that would otherwise be lost. By closing the loop, EPR plays a vital role in building a circular economy where waste becomes a resource.

Circular Economy and Urban Mining

Traditional disposal methods treat waste as an end point. In contrast, circular systems aim to reuse, refurbish, and recycle materials continuously. Electronics contain valuable metals such as gold, silver, palladium, and copper, embedded in circuit boards, batteries, and wiring.

Recovering these metals from e-waste:

- Reduces dependence on environmentally destructive mining

- Lowers greenhouse gas emissions and energy use

- Prevents pollution caused by unsafe and informal recycling practices

- Supports conservation of natural resources

The United Nations reports that up to seven percent of the world’s gold may be present in e-waste, yet less than twenty percent of global e-waste is formally recycled. EPR-driven recovery systems offer a way to bridge this gap and create long-term environmental and economic value.

How Re Sustainability Reldan Recovers Precious Metals

Recovering precious metals from electronics is a sophisticated scientific process. Re Sustainability Reldan uses a combination of pyrometallurgical and hydrometallurgical technologies to ensure maximum resource recovery while minimizing environmental impact.

The process includes:

Collection and Sorting

Electronics are gathered through formal take-back systems established under EPR programs.

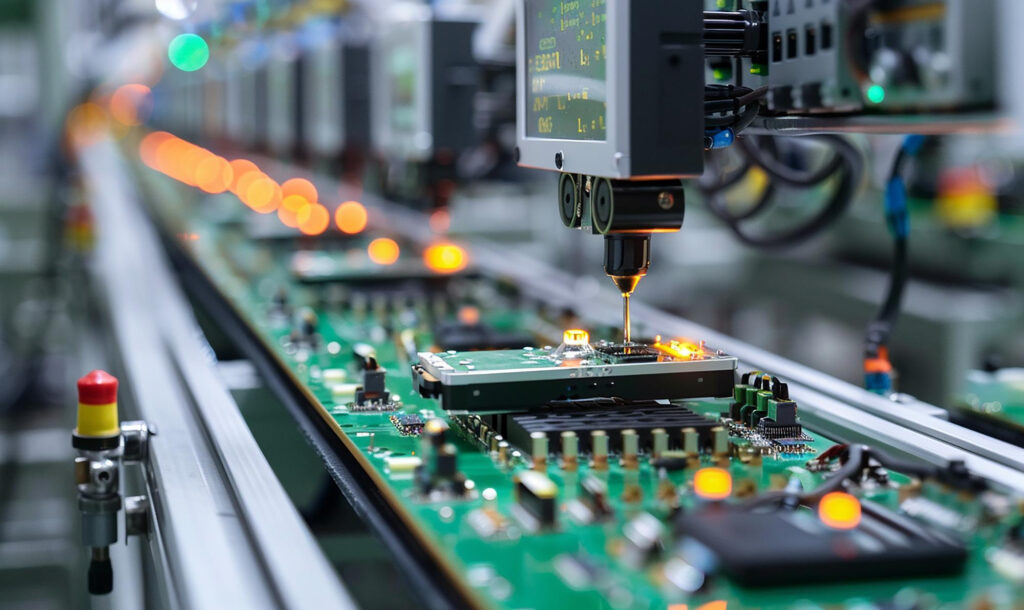

Dismantling

Components with high metal content, such as printed circuit boards and memory modules, are manually separated for processing.

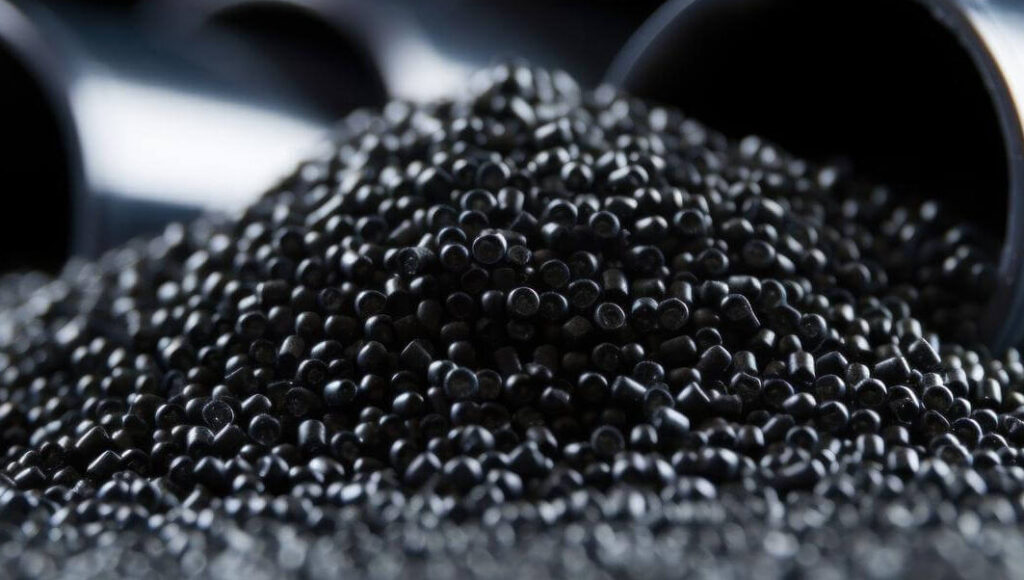

Shredding and Separation

Devices are mechanically shredded and then separated using magnetic, eddy-current, or density-based techniques to isolate metals from plastics and other materials.

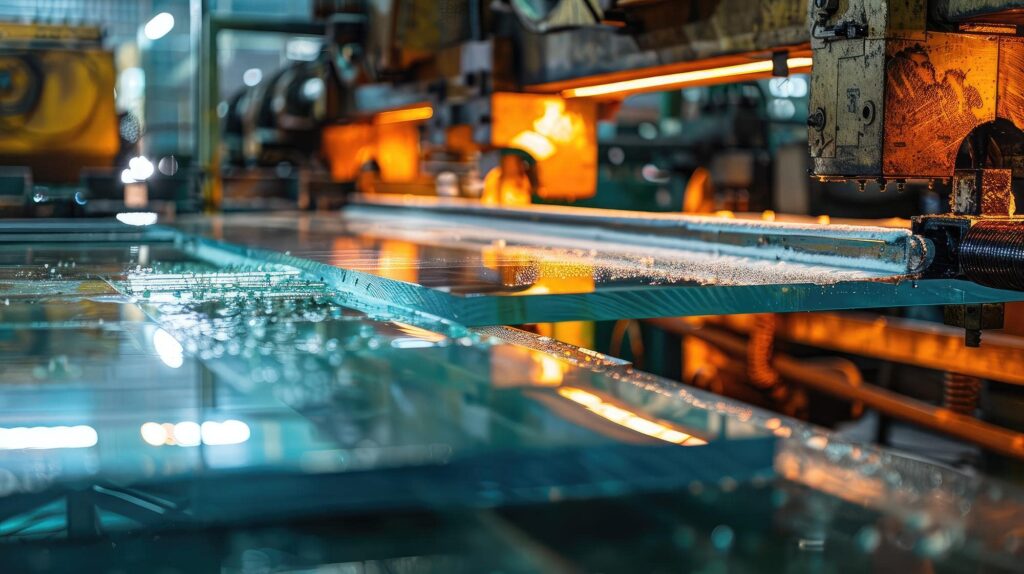

Precious Metal Processing

Advanced thermal and chemical methods are used to recover metals such as gold, silver, palladium, and copper. These materials are refined to industry-grade specifications and reintroduced into the manufacturing cycle.

By diverting e-waste from landfills and extracting usable materials, Re Sustainability Reldan enables a cleaner, more efficient resource loop that supports India’s transition to a low-carbon, sustainable economy.

Why EPR-Driven Recovery Matters for India

The benefits of EPR in the context of precious metal recovery go beyond environmental protection. When implemented with scale and integrity, EPR contributes to:

- Strengthening the formal recycling sector

- Creating green employment across collection, logistics, and processing

- Reducing reliance on imported metals and rare earth materials

- Preventing environmental damage from informal and unsafe recycling practices

- Supporting India’s sustainability commitments, including net-zero goals and alignment with the Sustainable Development Goals (SDGs)

Producers who partner with certified recyclers like Re Sustainability Reldan not only meet compliance requirements but also improve their brand’s environmental credentials in a growing market that values transparency and sustainability.

Challenges and the Road Ahead

India has made progress in building the EPR ecosystem, with digital tools like the EPR portal streamlining compliance and reporting. However, several challenges remain:

- Informal recyclers still process a large share of e-waste, often using hazardous methods

- Consumer participation in take-back programs remains low

- Many producers still treat EPR as a checkbox rather than a strategic sustainability initiative

To unlock the full potential of EPR, India needs stronger enforcement, consumer education, financial incentives for circular innovation, and ongoing investment in clean-tech infrastructure.

Conclusion

E-waste should not be seen as a liability but as an opportunity. With strong EPR frameworks and responsible partners like Re Sustainability Reldan, India has the tools to turn discarded electronics into valuable raw materials. This is more than recycling. It is a vision for a future where consumption and conservation go hand in hand.

By recovering precious metals from yesterday’s devices, we are protecting natural ecosystems, reducing climate impact, and creating a more resilient and resource-efficient economy. The journey toward a circular India is already underway. The next step is to scale it with urgency, innovation, and shared responsibility.

Categories

Recent Posts