How Electricity Helps Recover Precious Metals from

E-Waste and Manufacturing Scrap

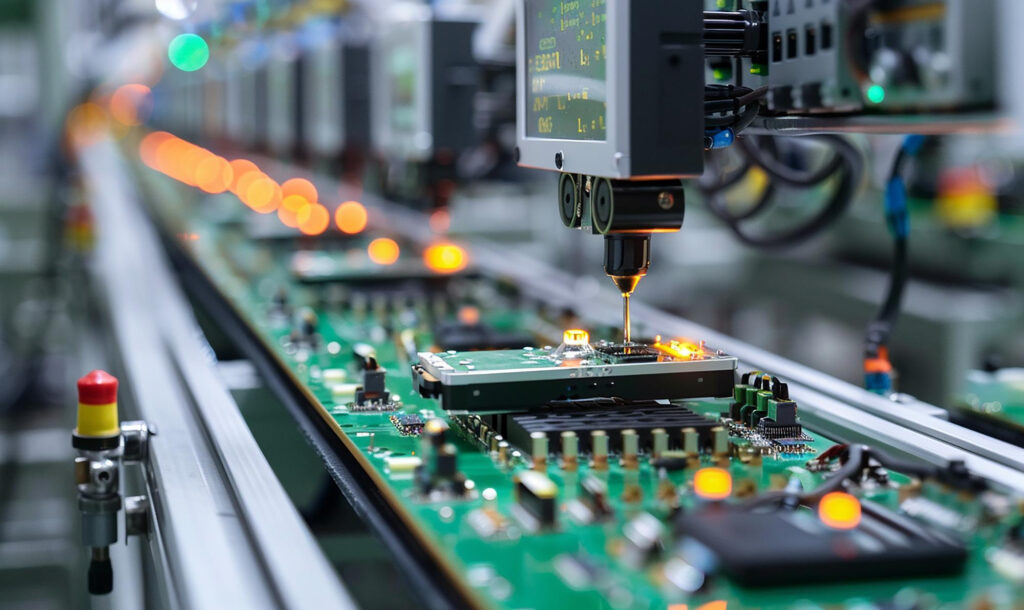

Every discarded circuit board, production reject, or worn-out component from electronic manufacturing holds hidden value. Inside these materials are trace amounts of gold, silver, palladium, and copper, vital for modern electronics but often lost due to inefficient or unsafe recycling methods.

With India generating over 1.75 million tonnes of e-waste annually and growing volumes of electronics manufacturing scrap, the challenge is clear: how do we safely and sustainably recover these precious metals?

One of the most reliable answers lies in a process called electrowinning,a proven method that uses electricity to recover high-purity metals. At ReReldan India, we’ve implemented a dedicated in-house system based on this technology, tailored for both post-consumer e-waste and electronics manufacturing residue.

What Is Electrowinning in Simple Terms?

Electrowinning might sound complex, but the core idea is straightforward: electricity is used to separate and collect metals from a solution. Here’s how it works in the context of electronic scrap:

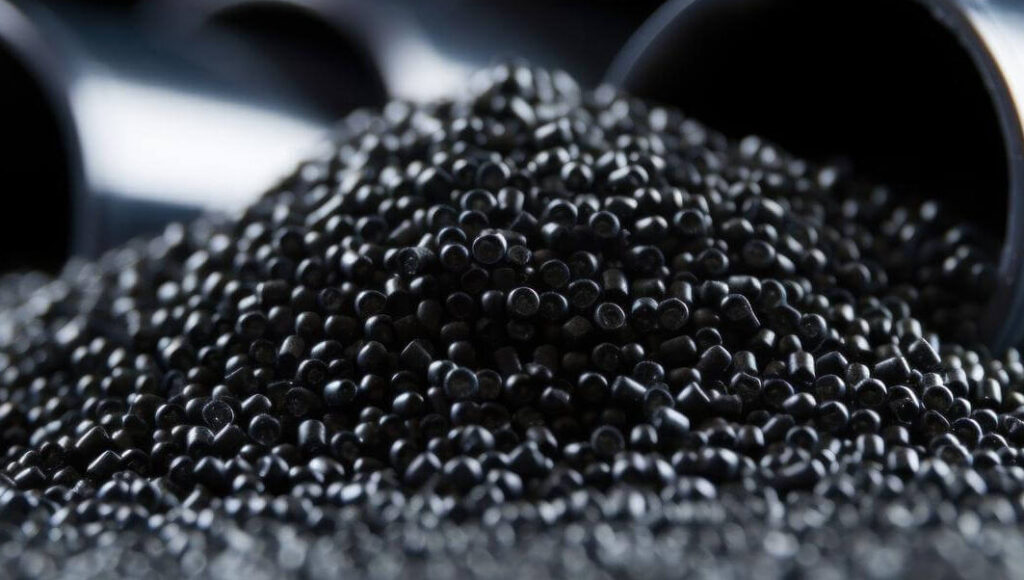

- Following safe, environmentally conscious dismantling and e-waste processing, valuable metals are gently extracted into a controlled liquid solution for responsible recovery.

- By applying a controlled electric current, precious metals like gold, silver, and copper are drawn out and deposited onto metal plates.

- These recovered metals are of high purity and ready for reuse across industries—whether in new electronics, industrial components, or jewelry.

In essence, electrowinning turns invisible value back into usable resources, with minimal waste and no open burning or uncontrolled chemical exposure.

Why It Matters for E-Waste & Electronics Manufacturing

Most recycling in India still happens in the informal sector, often using hazardous methods that damage both health and the environment. These crude techniques not only pollute but also waste the very metals we aim to recover.

By contrast, a controlled in-house recovery system like ours offers:

- Higher recovery yields from complex e-waste and process residues.

- Safe, closed-loop operations with no toxic discharge or air pollution.

- Compliance with global sustainability standards, ensuring confidence among international brands and local partners alike.

This approach not only protects the environment—it also ensures traceable, transparent metal recovery aligned with industrial needs.

Benefits Over Traditional Recycling Methods

Choosing an advanced method like electrowinning over traditional recycling has clear advantages:

- Purity: Recovered metals are clean and consistent, ready for direct reuse.

- Efficiency: Controlled processes allow faster, optimized recovery.

- Environmentally responsible: No smoke stacks, no acid runoff—just electricity and science.

- Tailored for electronics: Ideal for low-grade, high-complexity streams typical in manufacturing scrap and obsolete components.

Broader Applications Across the Value Chain

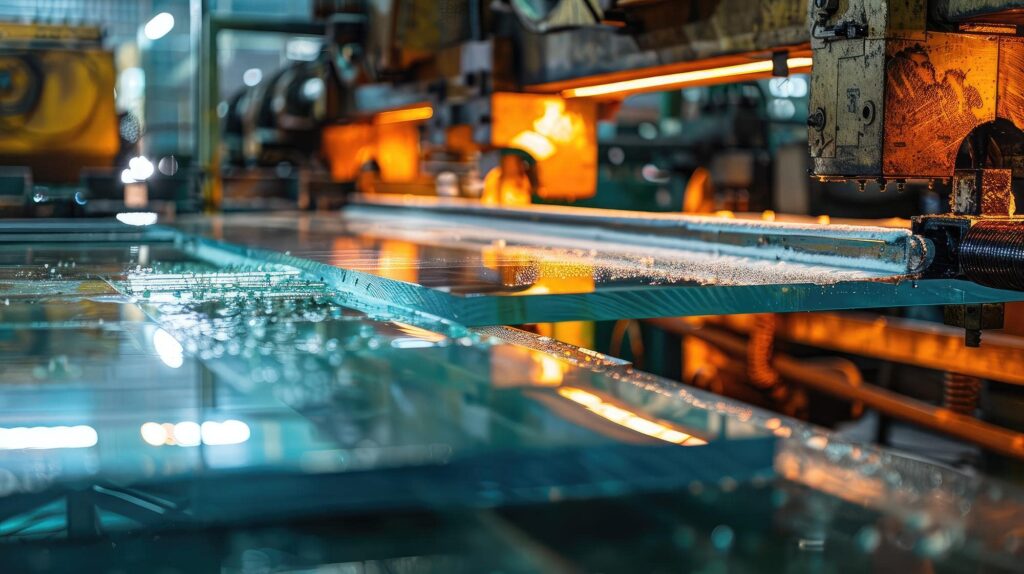

While e-waste is a major feedstock, our recovery system also caters to:

- Manufacturing rejects from PCB production, plating baths, or component assembly.

- Electronics repair or refurbishment scrap with residual metal value.

- OEM/EMS partners looking for sustainable disposal solutions aligned with circular economy goals.

This flexibility ensures that we support both post-consumer and industrial electronic waste streams, building a more holistic approach to precious metal recovery in India.

The Role of Trusted Recovery Facilities

Not all recyclers are created equal. Facilities with in-house refining capabilities and strong compliance protocols ensure that processes like electrowinning are executed with safety, efficiency, and accountability. As part of a global refining group, ReReldan India brings best-in-class systems, global traceability, and stakeholder transparency to every gram recovered.

Conclusion: Smart Recovery for a Smarter Industry

Precious metals are too valuable,economically and environmentally,to lose in landfills or low-efficiency recycling. With in-house recovery powered by electrowinning, we’re demonstrating how modern technology and sustainable thinking can solve a real-world challenge for India’s growing electronics ecosystem.

Whether you’re an OEM, EMS, or part of the broader circular economy, we invite you to partner with us in this transition from waste to value, from pollution to precision.

Categories

Recent Posts

-

How the Pharmaceutical Industry Can Unlock Value Through Precious Metal Recovery

How the Pharmaceutical Industry Can Unlock Value Through Precious Metal Recovery -

Why IT Asset Refurbishing Is Essential for Sustainable IT in 2026

Why IT Asset Refurbishing Is Essential for Sustainable IT in 2026 -

How Glass Manufacturers Improve Efficiency with Precious Metal Recovery

How Glass Manufacturers Improve Efficiency with Precious Metal Recovery -

Turning Glass Manufacturing Waste into Profit recovery refining solutions

Turning Glass Manufacturing Waste into Profit recovery refining solutions -

ESG and Regulatory Pressures Reshaping Precious Metal Refining

ESG and Regulatory Pressures Reshaping Precious Metal Refining -

Circular Economy in Electronics Manufacturing: Closing the Loop Through Precious Metal Recycling

Circular Economy in Electronics Manufacturing: Closing the Loop Through Precious Metal Recycling