How to Refine and Process Precious Metals with Minimal Environmental Impact

Precious metals like gold, silver, platinum, and palladium play a vital role in our everyday lives. From electronics and medical equipment to jewelry and industrial applications, these metals are everywhere. But behind their brilliance lies an important question: how can we refine and recycle precious metals without harming the environment?

At Re Sustainability Reldan, we specialize in precious metal processing, including refining methods that reduce environmental impact and we believe that sustainability & innovation go hand in hand. Refining metals doesn’t have to mean polluting air, water, or soil. With the right approach, it can actually support a circular economy – where valuable resources are recovered, reused, and kept in circulation for longer.

Why Traditional Precious Metal Processing Can Be Harmful

Conventional refining methods often rely on toxic chemicals such as cyanide or mercury, which can contaminate ecosystems and pose serious health risks. Additionally, high-energy smelting processes can release greenhouse gases and contribute to climate change.

This is why modern precious metal refining companies are shifting toward cleaner, safer, and more sustainable alternatives.

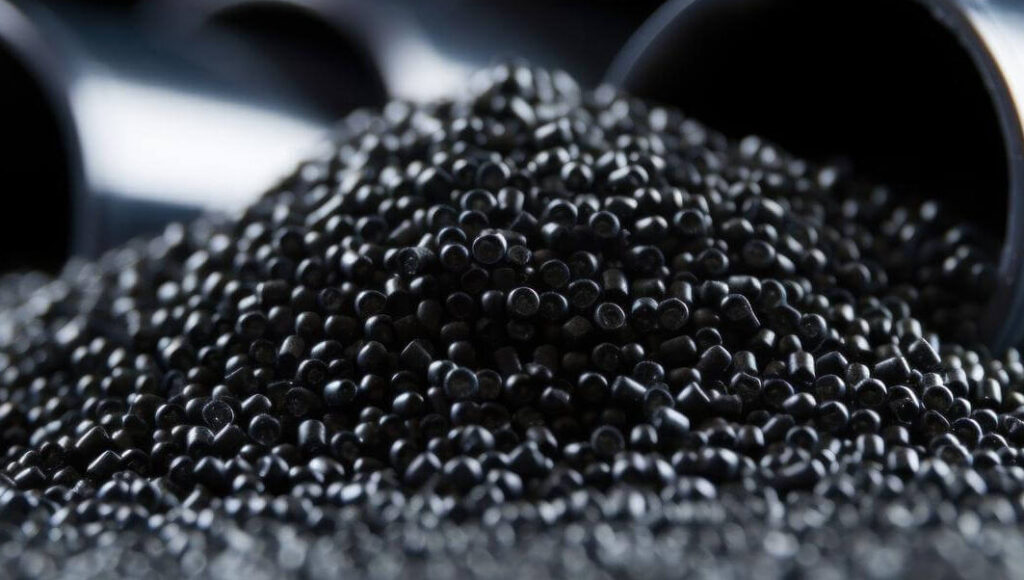

Eco-Friendly Precious Metal Recycling Process

Here are some ways to minimize environmental impact during refining:

1. Advanced Hydrometallurgical Techniques

Many facilities now extract metals using water-based solutions and eco-friendly reagents instead of harmful chemicals. These processes generate fewer emissions and reduce hazardous waste.

2. Efficient Precious Metals Management

A big part of sustainability lies in how materials are handled. Proper collection, segregation, and storage of e-waste, industrial scrap, and jewelry residues prevent contamination and maximize recovery.

3. Closed-Loop Systems

Modern refineries are adopting closed-loop systems where water, heat, and chemicals are reused multiple times. This minimizes waste and conserves resources.

4. Responsible Emission Control

Air pollution is a major concern in smelting. By using advanced filtration systems and emission controls, precious metal refining companies can reduce harmful releases and improve air quality.

5. Energy-Efficient Technologies

Switching to renewable energy sources or optimizing furnace designs helps reduce carbon footprints. Some companies even recover heat from their refining process and reuse it in other operations.

The Human Side of Sustainable Refining

Beyond technology, sustainable refining is also about people. Safe working conditions, proper training, and community engagement ensure that the precious metal recycling process benefits everyone – not just businesses.

At Re Sustainability Reldan, we see ourselves as stewards of resources. Every gram of metal recovered through safe, sustainable methods means less mining, less pollution, and more value returned to industries and society.

Why Choose Sustainable Refining Companies?

By working with environmentally responsible precious metal refining companies, industries can:

- Reduce their carbon footprint

- Comply with stricter environmental regulations

- Strengthen their ESG (Environmental, Social, and Governance) commitments

- Build trust with customers who care about sustainability

In short, eco-friendly precious metals management is not just a responsibility – it’s also a smart business choice.

Final Thoughts

Precious metals are too valuable to waste, and the planet is too important to ignore. Refining metals with minimal environmental impact is possible through innovative technologies, efficient management, and a commitment to sustainability.

At Re Sustainability Reldan, we are proud to be part of this movement, setting new benchmarks in precious metal processing and recycling for a greener, safer future.

Categories

Recent Posts

-

How the Pharmaceutical Industry Can Unlock Value Through Precious Metal Recovery

How the Pharmaceutical Industry Can Unlock Value Through Precious Metal Recovery -

Why IT Asset Refurbishing Is Essential for Sustainable IT in 2026

Why IT Asset Refurbishing Is Essential for Sustainable IT in 2026 -

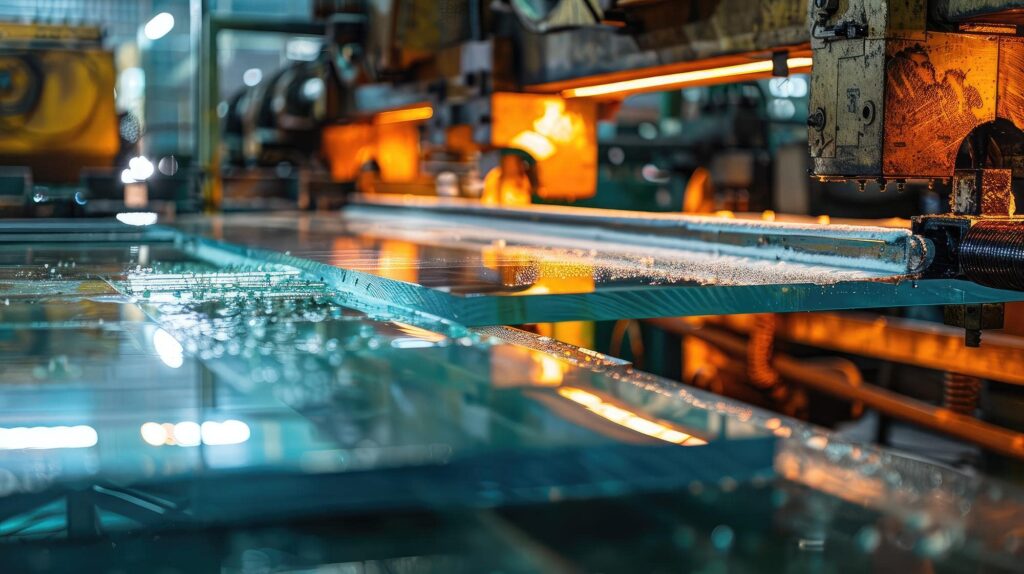

How Glass Manufacturers Improve Efficiency with Precious Metal Recovery

How Glass Manufacturers Improve Efficiency with Precious Metal Recovery -

Turning Glass Manufacturing Waste into Profit recovery refining solutions

Turning Glass Manufacturing Waste into Profit recovery refining solutions -

ESG and Regulatory Pressures Reshaping Precious Metal Refining

ESG and Regulatory Pressures Reshaping Precious Metal Refining -

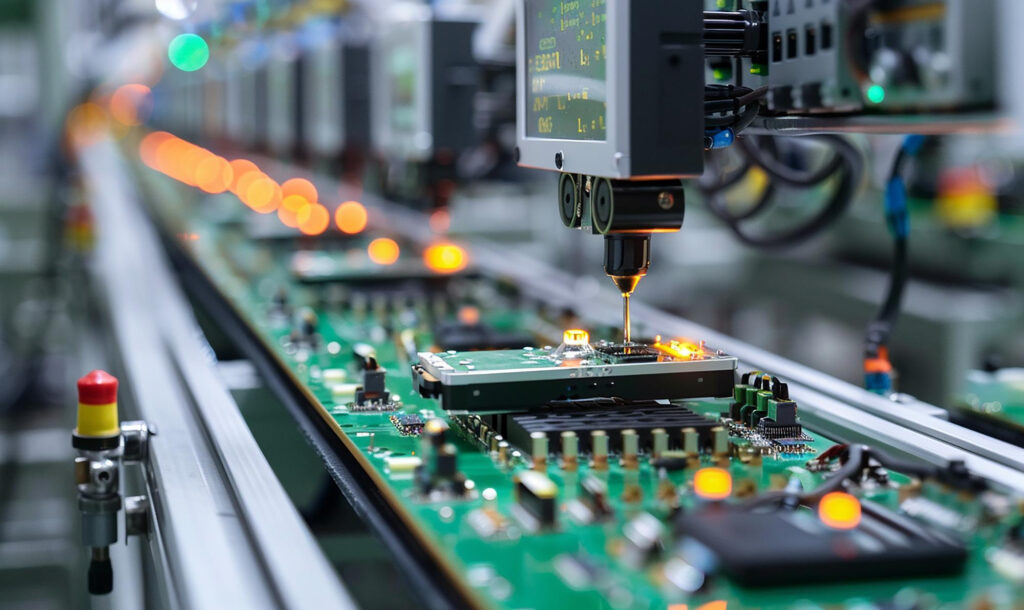

Circular Economy in Electronics Manufacturing: Closing the Loop Through Precious Metal Recycling

Circular Economy in Electronics Manufacturing: Closing the Loop Through Precious Metal Recycling