How Re Sustainability Reldan Uses Technology

to Recover Metals for High-Quality Plating

Every year, tons of electronic and industrial waste end up discarded, often containing valuable precious metals like gold, silver, and palladium. These metals are essential for high-quality plating used in electronics, automotive parts, and precision manufacturing. Yet, much of this value is lost due to outdated or unsustainable recovery methods.

At Re Sustainability Reldan, we’re changing that.

By integrating advanced technologies with decades of refining expertise, we recover these metals efficiently and responsibly, minimizing environmental impact while delivering materials that meet the plating industry’s stringent quality standards. Our approach ensures that sustainability isn’t just a buzzword but a built-in part of the supply chain for businesses looking to meet both performance and ESG goals.

Why Metal Recovery Matters More Than Ever

Metals like gold, silver, palladium, and platinum are essential for plating in electronics, jewelry, and other industries. But mining these metals is energy-intensive, polluting, and often unsustainable.

At Re Sustainability Reldan, we take a different approach:

We recover metals from industrial and consumer waste, transforming what was once considered scrap into valuable raw materials.

Our Technology Approach

Here’s how we recover metals sustainably:

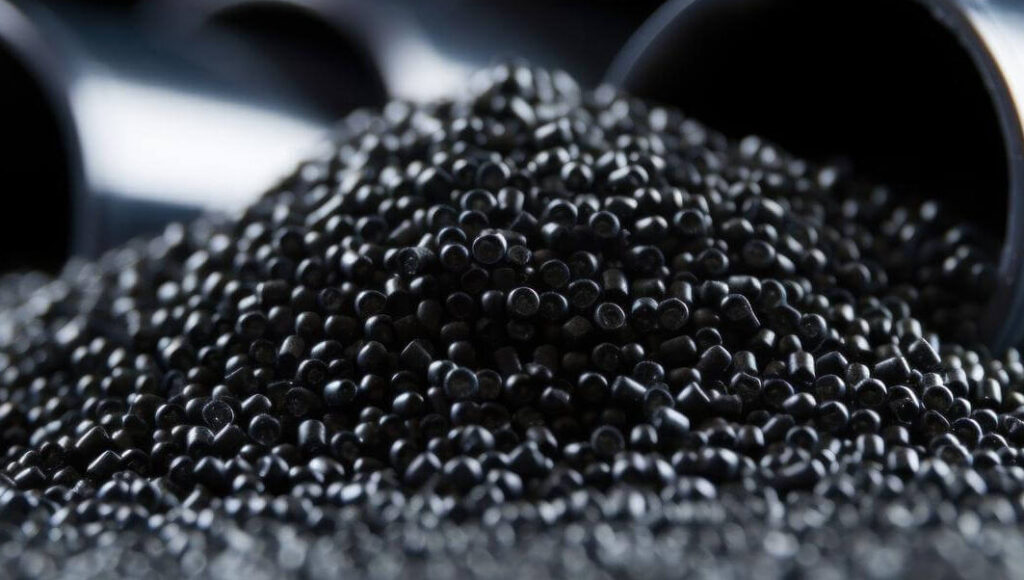

- Advanced Shredding & Mechanical Separation – We begin by breaking down scrap and e-waste using multi-stage shredding, sieving, and air classification systems. These processes isolate high-metal-content materials without harmful emissions.

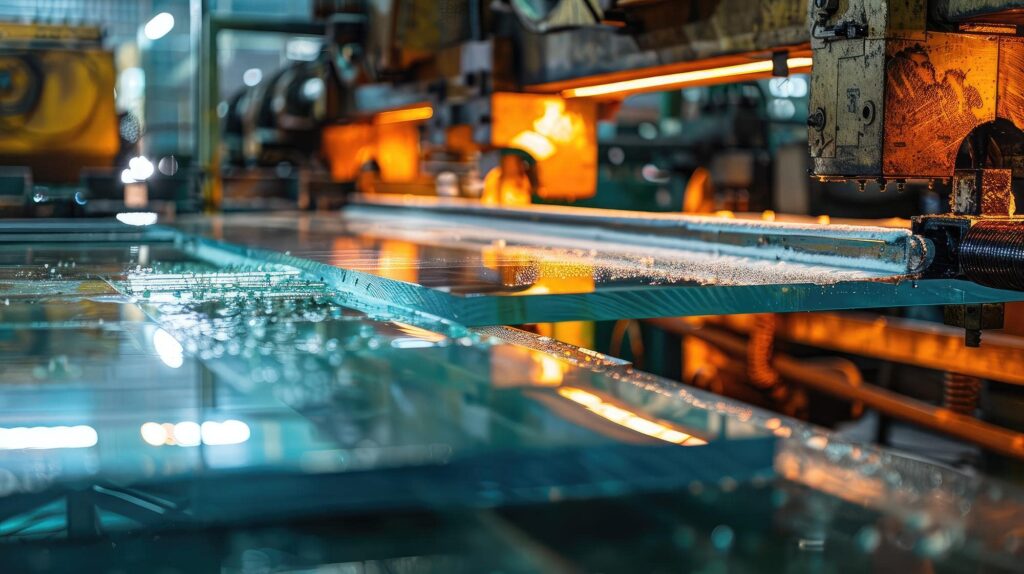

- Thermal & Chemical Recovery – Next, we extract metals using pyrometallurgy and hydrometallurgy. These methods are fine-tuned to reduce energy consumption and prevent hazardous byproducts.

- Eco-Safe Refining – All recovery takes place in controlled, certified environments, ensuring there’s no leaching, toxic discharge, or uncontrolled burning, practices still common in informal recycling operations elsewhere.

Advanced Precious Metal Recovery in Plating Solutions Using Gold Bug® Technology

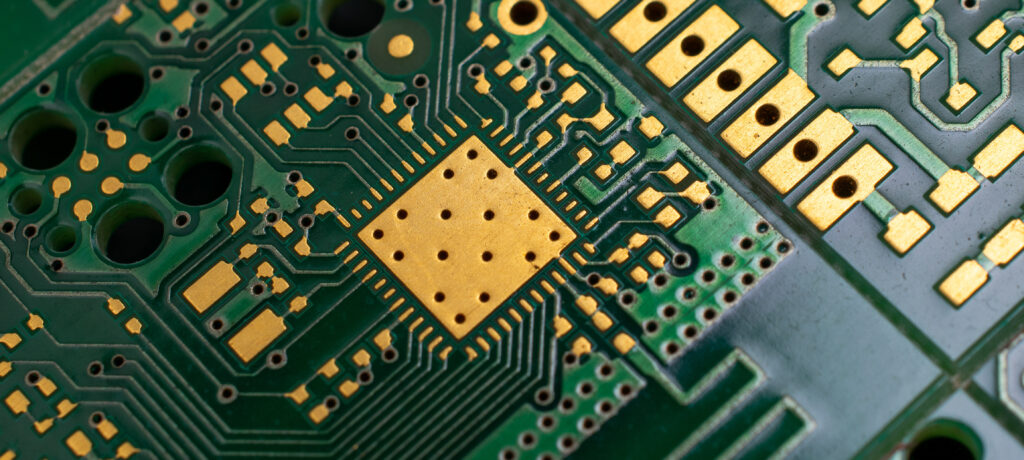

As part of our focus on sustainable plating solutions, we are proud to integrate advanced electrolytic recovery systems such as the Gold Bug® by Precious Metals Processing Consultants, Inc (PMPC). With over 30 years of expertise, PMPC has pioneered innovative electrolytic metal recovery technologies designed to recover heavy and precious metals from a wide range of solutions and pH levels. The Gold Bug® system is especially effective in treating plating bath drag-outs and rinse waters, bringing metal concentrations down to environmental compliance levels even below 5ppm, and in some cases, to undetectable limits.

The Gold Bug® is proven to recover silver, palladium, palladium-nickel, platinum, rhodium, iridium, and also base metals like copper, cadmium, tin, and tin-lead. Its unique high-surface-area cathode design enables it to fit into small drag-out tanks while still handling large volumes of concentrated cyanide or acid strip solutions. Whether for off-the-shelf units or custom-designed systems, Gold Bug® supports circularity in plating operations by enabling the efficient, cost-effective recovery of precious metals.

LEED-Certified Facilities

Our commitment to sustainability isn’t limited to what we do; it extends to where we do it.

- Our India facilities are LEED Platinum certified, and they use solar energy, rainwater harvesting, and optimized air quality controls.

Industry Applications: From E-Waste to Jewelry

Re Sustainability Reldan’s metal recovery services support several industries:

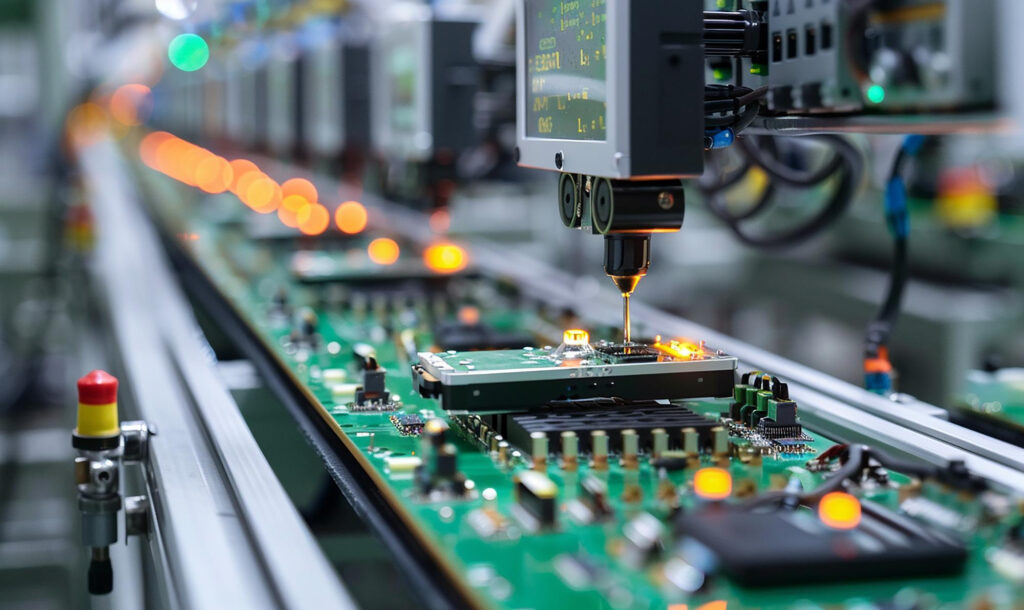

- Electronics: We extract valuable metals from circuit boards, connectors, and devices.

- Jewelry: We recover fine dust, polishing residue, and manufacturing scrap, maximizing yield from every gram.

- Manufacturing: From aerospace to automotive, we supply high-purity metals reclaimed responsibly.

Quality You Can Trust

We operate under globally recognized best practices and have been awarded the following certifications:

- ISO 9001:2015 – for Quality Management Systems

- ISO 14001:2015 – for Environmental Management Systems

- ISO 45001:2018 – for Occupational Health and Safety Management Systems

- LEED Platinum Certification – from the U.S. Green Building Council, recognizing our Hyderabad facility as one of the most energy- and resource-efficient of its kind in Asia.

Why Choose Re Sustainability Reldan?

- High recovery efficiency

- Eco-conscious processes

- Full traceability & compliance

- Support for your ESG goals

Conclusion

At Re Sustainability Reldan, we believe waste is not the end, it’s a beginning. By recovering metals through clean, efficient technologies, we help our clients reduce costs, improve sustainability, and ensure quality in everything they build or plate.

Categories

Recent Posts