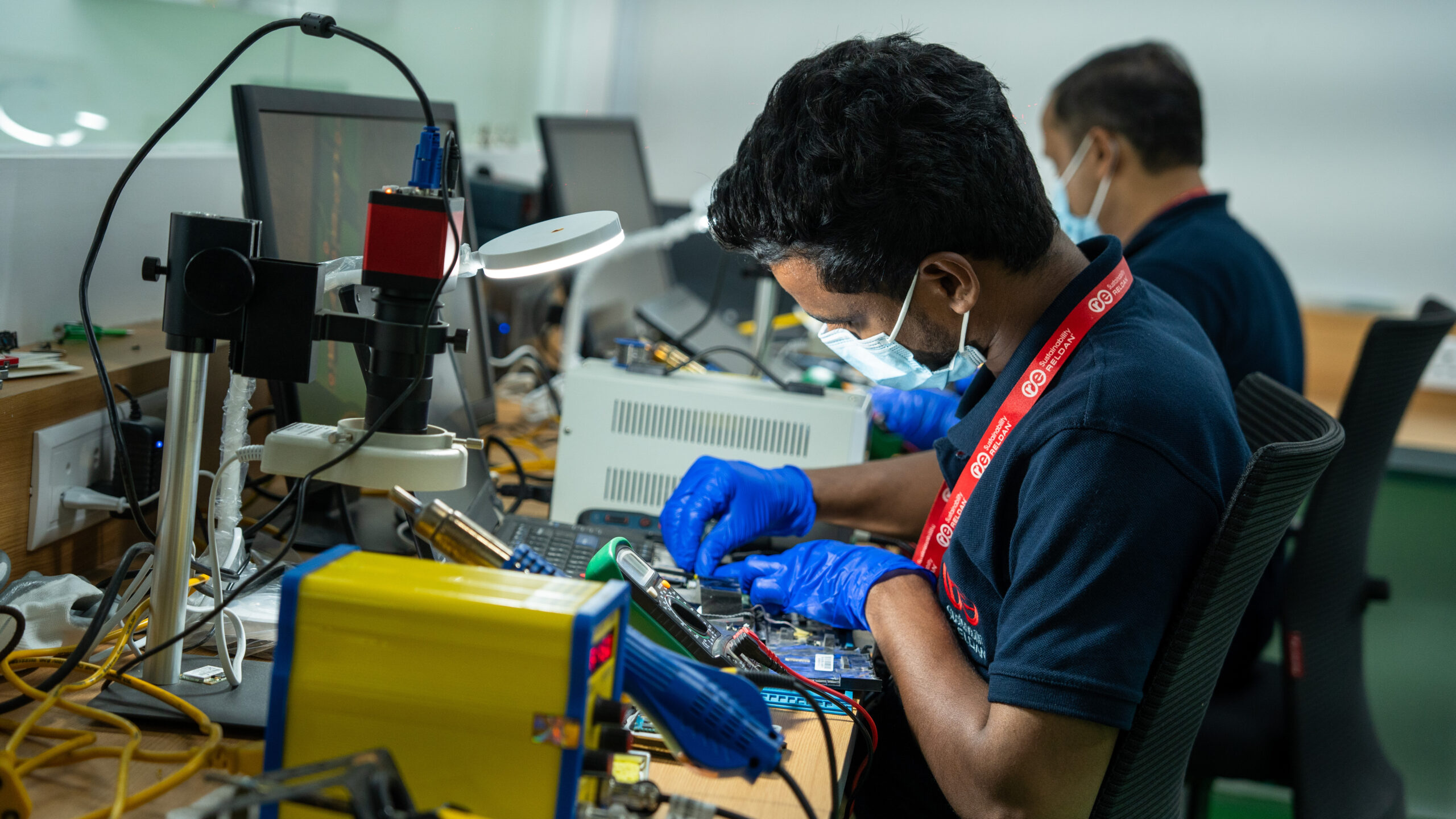

Core Refining Capabilities

As a leading e-waste management and precious metal recycling solution provider in India, we utilize advanced technology and unique expertise to sustainably refine a diverse range of precious metals, optimizing value and efficiency from metal waste streams.

At ReReldan, our advanced e-waste recycling and processing systems are designed for high-efficiency precious metal recovery. Using cutting-edge mechanical, thermal, and chemical techniques, we extract valuable metals such as gold, silver, palladium, and copper — reducing raw material dependency and advancing a sustainable circular economy. Our integrated metal recovery and waste processing technologies help industries recover precious metals responsibly and efficiently

Thermal

Re Sustainability Reldan has several thermal destruct units at its disposal, including a continuous feed rotary incinerator and a single chamber, small batch furnace. By utilizing these units, we can offer you the best value for your materials, expedite the return process, and minimize waste generation, resulting in a more sustainable operation.

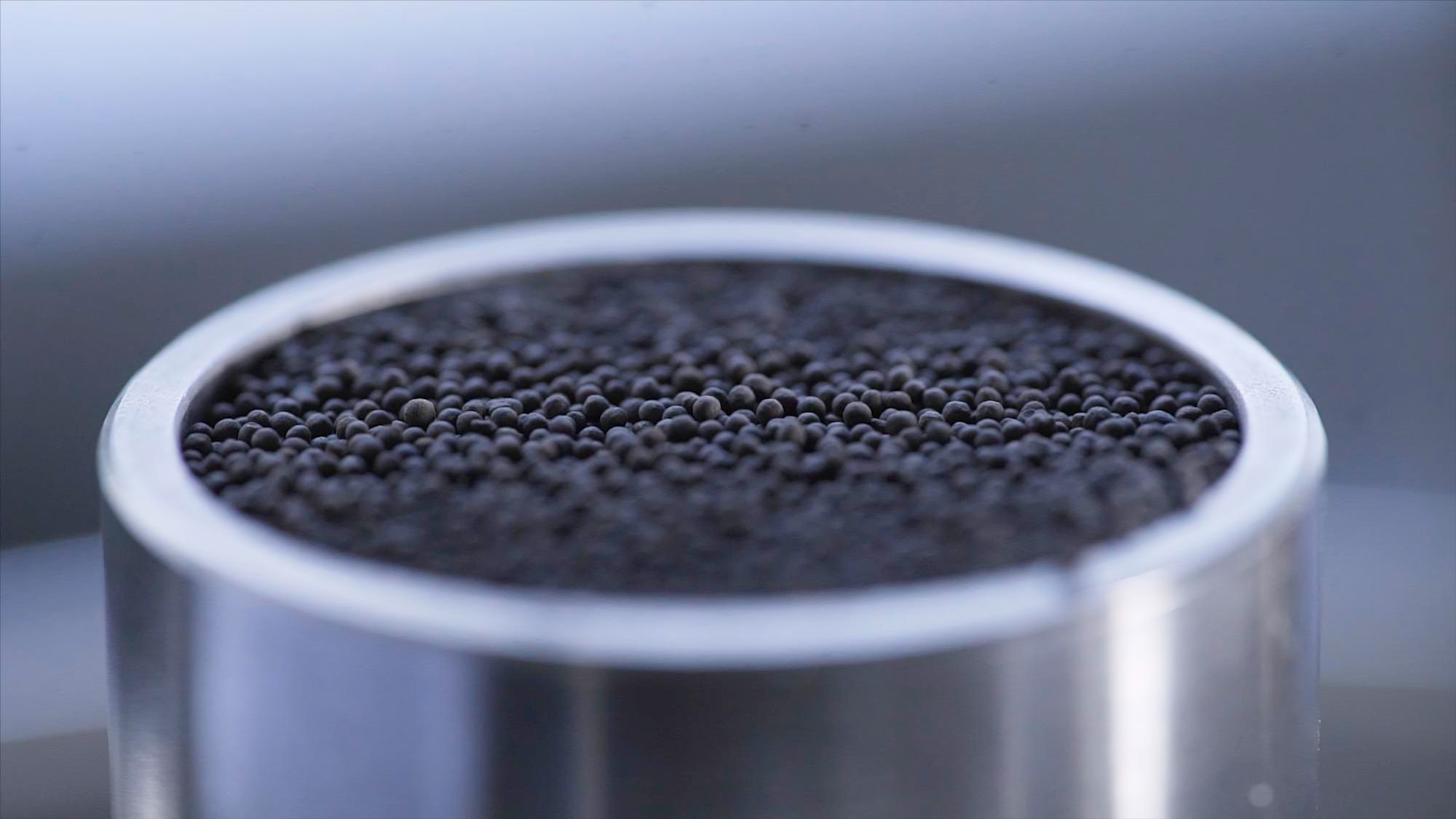

Mechanical Reduction

Our advanced, 4-stage system was built specifically to maximize the value of precious metal scrap material. This process breaks down, sorts, and separates, while simultaneously an advanced dust collection system reclaims every valuable particle so you get the best return on your precious metal waste streams. Our 4-stage process is not only more accurate but also a much faster way to process your material resulting in faster processing.

Melting

Our furnaces can process the rarest materials containing precious metals. Our distinctive process allows for the best value of precious metal recovery in the most sustainable way. We create a sample that can be broken down in a way that ensures we deliver maximum value, and eliminate most process chemicals that can be harmful to the environment.

Chemical

We use an exclusive chemical blend that streamlines your precious metal for quicker turnaround times. Our multi-stage blending tanks and super natant testing ensures the best value for your precious metal scrap. Our completely self-contained chemical processing facilities prevents environmental runoff and no wasted material in landfills for a cleaner, more sustainable operation.

Materials We Process

We specialize in managing a diverse array of waste materials. We transform e-waste, industrial metals, bio-medical waste, and municipal solid waste into sustainable resources. Our electrowinning solution operates as a critical stage within a comprehensive e-waste processing and recycling workflow that includes collection, controlled shredding, chemical processing, and the final recovery of high-purity metals.

Efficiently process electronic waste to extract valuable precious metals and reduce landfill burden.

Efficiently process electronic waste to extract valuable precious metals and reduce landfill burden.

Secure, compliant IT asset disposal solutions ensuring data protection and sustainable value recovery.

Our team employees advanced methods to transform outdated gadgets into high-performance assets, promoting sustainability and efficiency. Data Security and logical data sanitization